A circular economy is a sustainable economic model that deviates from the traditional linear system of "take, make, dispose" and promotes a loop of regeneration where resources are continually reused, refurbished, and recycled. This economic model presents a paradigm shift, focusing on eliminating waste, reducing resource consumption, and ensuring long-term environmental sustainability. At its core, a circular economy aims to design out waste, keep products and materials in use for longer, and regenerate natural systems. Its fundamental principles echo many of the aspirations set out by the United Nations in the Sustainable Development Goals (SDGs). The SDGs, established in 2015, encompass a broad range of global objectives intended to end poverty, protect the planet, and ensure prosperity for all by 2030. The relationship between the circular economy and SDGs is intrinsic and mutually reinforcing.

Consider, for instance, SDG 12, which promotes responsible consumption and production. A circular economy directly supports this goal by advocating for the efficient use of resources, minimizing waste, and promoting sustainable consumption patterns. The manufacturing processes in a circular model emphasize product longevity, reparability, and recyclability, which inherently leads to reduced resource extraction and waste generation. By doing so, we can make significant strides towards achieving other SDGs, such as clean water and sanitation (SDG 6) and climate action (SDG 13). By designing products for longevity and reusability, industries can also play a pivotal role in combating the global challenges of water scarcity, environmental degradation, and greenhouse gas emissions.

Additionally, a circular economy has the potential to stimulate economic growth and job creation, thus contributing to SDG 8 (decent work and economic growth). As businesses shift towards sustainable models of production, new opportunities emerge in sectors related to recycling, refurbishment, and product-service systems. These opportunities not only bolster economic growth but can also promote innovation (SDG 9) as companies invest in research and development to create sustainable solutions.

Furthermore, by valuing the resources at every stage of their lifecycle, a circular economy can significantly reduce the environmental impact of industries, supporting life below water (SDG 14) and life on land (SDG 15). For instance, by reducing plastic waste, we can mitigate its harmful effects on marine life and ecosystems. Similarly, by curbing deforestation for resource extraction, we can ensure the survival of diverse terrestrial ecosystems and the species that inhabit them.

The transition to a circular economy serves as a robust mechanism to achieve multiple SDGs simultaneously. It offers a holistic, systemic approach to address numerous global challenges ranging from resource scarcity to environmental degradation and from economic stagnation to unemployment. Adopting the principles of a circular economy can accelerate our journey towards a sustainable, inclusive, and prosperous future as envisioned by the Sustainable Development Goals.

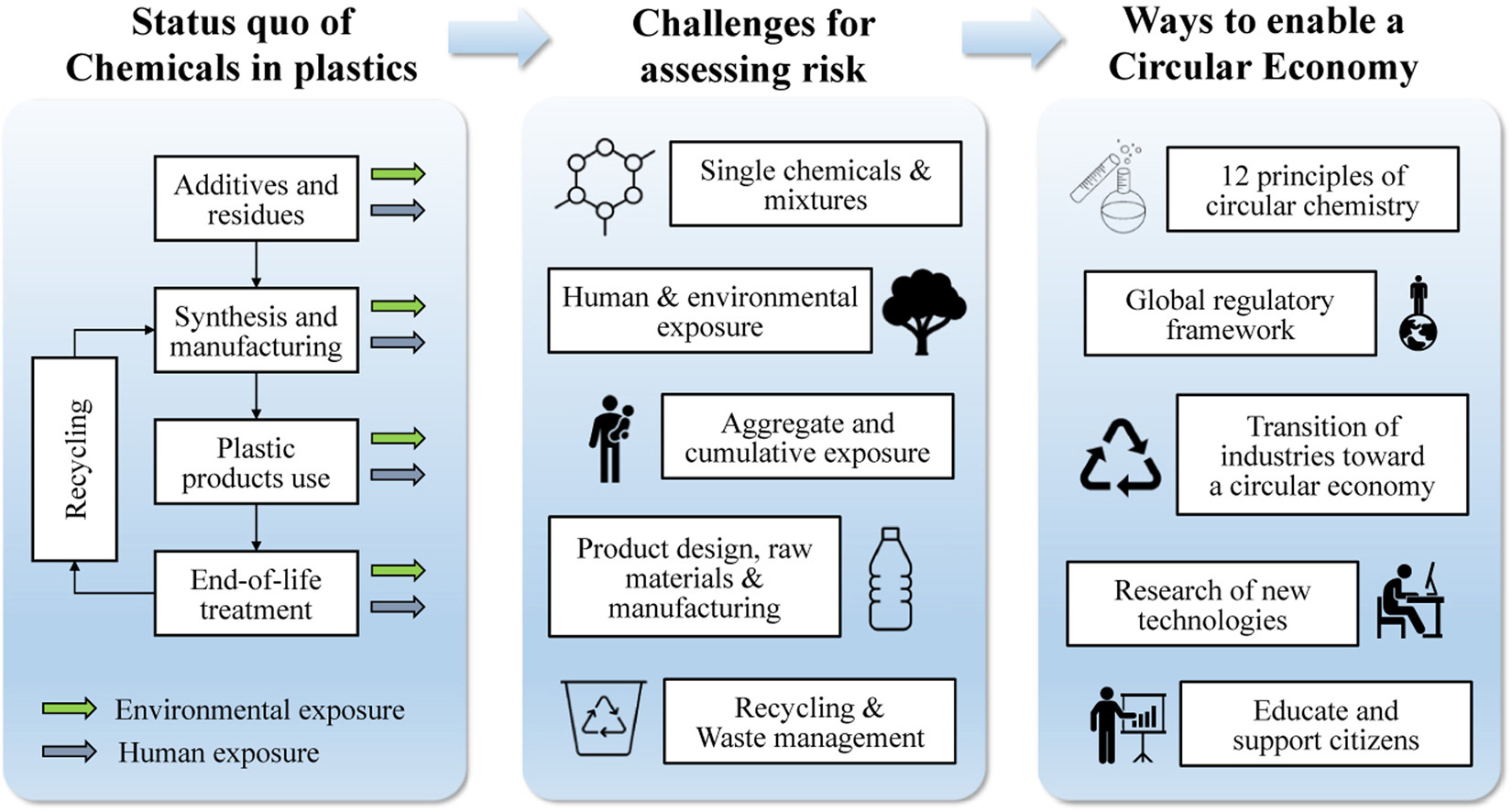

Enabling a circular economy for plastics in Europe and beyond is an ambitious goal. To reach a fully closed loop, numerous challenges and knowledge gaps need to be overcome. This review provides a list of more than 6000 chemicals reported to be found in plastics and an overview of the challenges and gaps in assessing their impacts on the environment and human health along the life cycle of plastic products. We further identified 1518 plastic-related chemicals of concern, which should be prioritized for substitution by safer alternatives.

Miguel Angel Gardetti, Chapter 1 - Introduction and the concept of circular economy, Editor(s): Subramanian Senthilkannan Muthu, In The Textile Institute Book Series, Circular Economy in Textiles and Apparel, Woodhead Publishing, 2019, Pages 1-11, ISBN 9780081026304,

https://doi.org/10.1016/B978-0-08-102630-4.00001-7.

Sustainable manufacturing extends beyond the manufacturing process and the product, to include the supply chain, across multiple product life-cycles as well as end-of-life considerations. Companies can gain a competitive advantage by applying sustainability manufacturing for environmental friendlier products and operations. Industry 4.0 sets new requirements for becoming a sustainable manufacturer where data management, the Internet of Things and extended product service systems are tightly linked with traditional manufacturing processes.