Lithium-ion batteries have become a cornerstone of modern energy storage technology, profoundly influencing various sectors and intersecting with multiple Sustainable Development Goals (SDGs). These batteries are known for their high energy density, long lifespan, and reusability, characteristics that make them particularly suitable for a range of applications, from small electronics to large-scale energy storage systems.

One of the primary SDGs impacted by lithium-ion batteries is SDG 7, Affordable and Clean Energy. These batteries play a crucial role in renewable energy systems, especially in storing energy from intermittent sources like solar and wind. By enabling efficient storage and release of renewable energy, lithium-ion batteries facilitate the shift away from fossil fuels, contributing to a more sustainable and less carbon-intensive energy grid. This shift is critical for meeting the global energy demand sustainably and affordably.

Moreover, lithium-ion batteries significantly contribute to SDG 11, Sustainable Cities and Communities, and SDG 13, Climate Action. The advent of electric vehicles (EVs) powered by lithium-ion batteries has revolutionized the transport sector, offering a cleaner alternative to traditional gasoline and diesel-fueled vehicles. By reducing the reliance on fossil fuels for transportation, these batteries help decrease greenhouse gas emissions and urban air pollution, making cities more sustainable and habitable. This transition to electric vehicles is integral to mitigating climate change and promoting healthier urban environments.

However, the production and disposal of lithium-ion batteries present challenges that resonate with SDG 12, Responsible Consumption and Production, and SDG 8, Decent Work and Economic Growth. The extraction of lithium, a key component of these batteries, often leads to environmental degradation, including water depletion and pollution. This extraction process poses significant ecological risks, especially in lithium-rich regions. Furthermore, concerns about labor practices in lithium mining highlight the need for ethical and sustainable supply chains. Ensuring that the lithium used in batteries is sourced responsibly and ethically is crucial for aligning the production of these batteries with sustainable development principles.

Additionally, the end-of-life management of lithium-ion batteries poses a challenge. As the usage of these batteries surges, so does the need for effective recycling and disposal methods. Proper recycling of lithium-ion batteries can recover valuable materials, reduce the environmental impact, and support sustainable production practices.

The impact of lithium-ion batteries extends to other SDGs as well. For instance, by enabling the expansion of renewable energy, they indirectly support SDG 13, Climate Action, by contributing to the reduction of global greenhouse gas emissions. Moreover, by fostering the growth of the renewable energy sector, they contribute to SDG 8, Decent Work and Economic Growth, by creating new job opportunities and stimulating economic development.

Economically viable electric vehicle lithium-ion battery recycling is increasingly needed; however routes to profitability are still unclear. We present a comprehensive, holistic techno-economic model as a framework to directly compare recycling locations and processes, providing a key tool for recycling cost optimization in an international battery recycling economy. We show that recycling can be economically viable, with cost/profit ranging from (−21.43 - +21.91) $·kWh−1 but strongly depends on transport distances, wages, pack design and recycling method.

Lithium-ion batteries (LIBs) have an established role in the consumer electronics markets with minimum risk of replacement from any other contender in the near future. The recent momentum towards electric vehicles and the renewable energy storage market is creating an increased demand for LIBs. The large amount of hazardous waste generated from the disposal of LIBs is driving research into a sustainable approach for LIB treatment and recovery. The positive electrode active materials being the main targeted component as it is the greatest cost contributor to LIBs production.

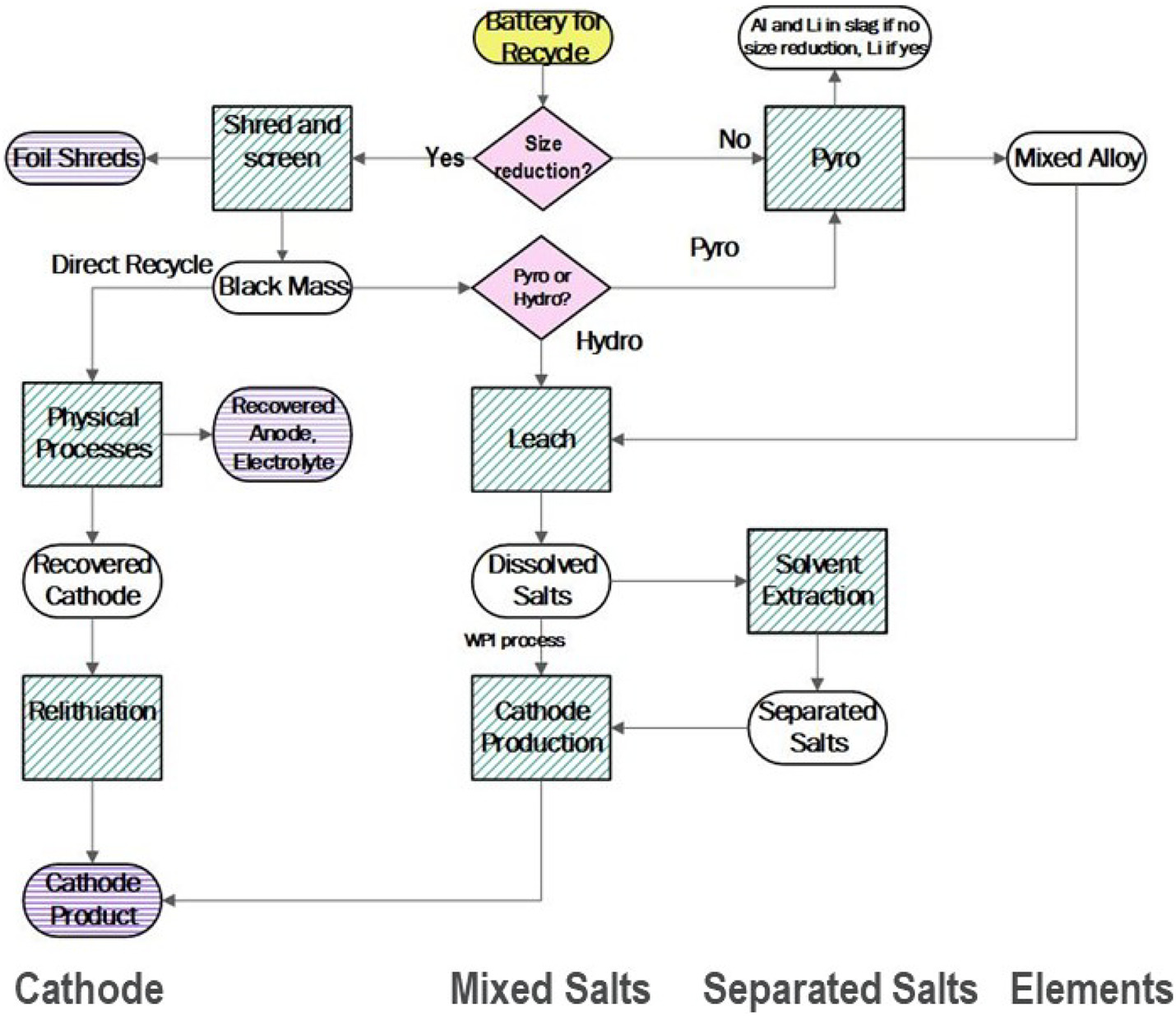

There is a need to develop technology to enable a resource-efficient and economically feasible recycling system for lithium-ion batteries and thus assure the future supply of the component materials. Lithium-ion batteries are complex products, and designs and materials are still evolving, which makes planning for future recovery more challenging. Several processes for recycling are proposed or operating, and each has advantages and disadvantages. This paper compares these processes on technical and economic bases, elucidating differences in benefits as a function of cathode composition.

This paper looks ahead, beyond the projected large-scale market penetration of vehicles containing advanced batteries, to the time when the spent batteries will be ready for final disposition. It describes a working system for recycling, using lead-acid battery recycling as a model. Recycling of automotive lithium-ion (Li-ion) batteries is more complicated and not yet established because few end-of-life batteries will need recycling for another decade. There is thus the opportunity now to obviate some of the technical, economic, and institutional roadblocks that might arise.