High-tech products like batteries and electronics contain a variety of valuable, scarce, and in some cases potentially harmful materials, but in only a few exceptional cases (such as lead-acid batteries) is the material being recovered efficiently. Cotributing to SDGs 7, 9 and 12, this special issue seeks to elucidate the technical and institutional difficulties inherent in recycling these products and provide a forum for sharing potential ways to overcome them.

Sustainable Materials and Technologies, Volume 23, April 2020

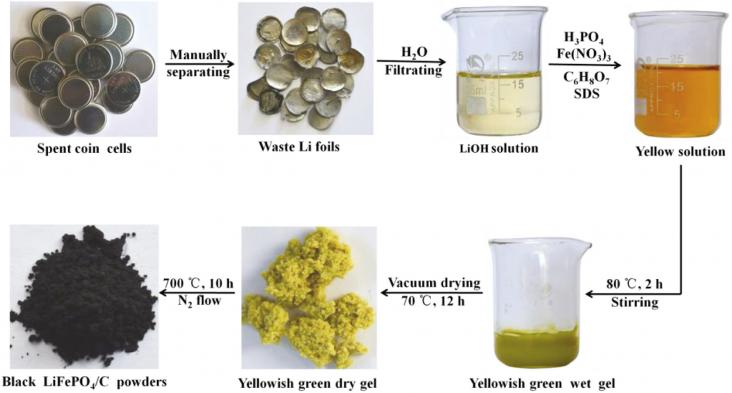

Lithium-ion batteries (LIBs) have an established role in the consumer electronics markets with minimum risk of replacement from any other contender in the near future. The recent momentum towards electric vehicles and the renewable energy storage market is creating an increased demand for LIBs. The large amount of hazardous waste generated from the disposal of LIBs is driving research into a sustainable approach for LIB treatment and recovery. The positive electrode active materials being the main targeted component as it is the greatest cost contributor to LIBs production.

Sustainable Materials and Technologies, Volume 17, September 2018

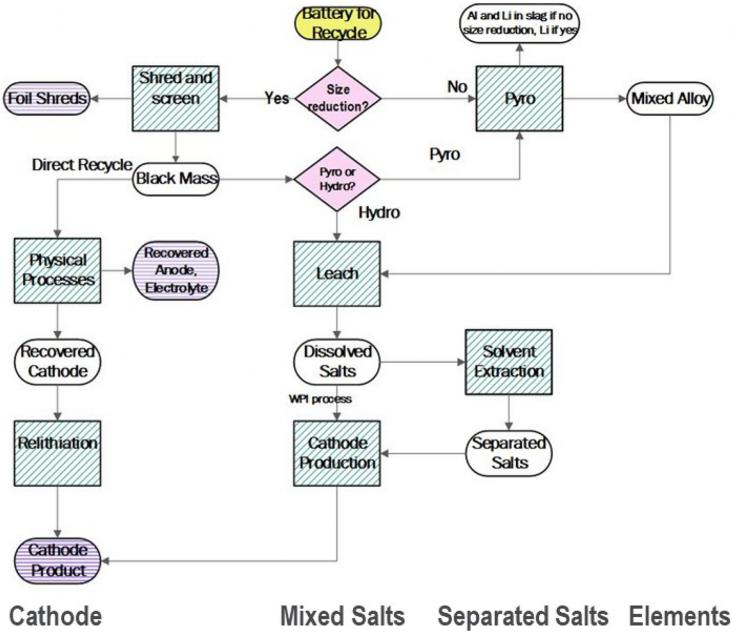

There is a need to develop technology to enable a resource-efficient and economically feasible recycling system for lithium-ion batteries and thus assure the future supply of the component materials. Lithium-ion batteries are complex products, and designs and materials are still evolving, which makes planning for future recovery more challenging. Several processes for recycling are proposed or operating, and each has advantages and disadvantages. This paper compares these processes on technical and economic bases, elucidating differences in benefits as a function of cathode composition.